Traction Evolved: Advancements in Tire Design for Diverse Terrains

Chosen theme: Advancements in Tire Design for Diverse Terrains. Explore how breakthrough compounds, smarter carcasses, and intelligent tread patterns redefine grip from deserts to glaciers. Join the journey, share your terrain stories, and subscribe for field-tested insights and behind-the-scenes engineering notes.

Self-cleaning lugs for mud mastery

Mud tires use deep voids, stepped shoulders, and ejector bars to shed clay before it packs and smooths the tread. Angled lateral channels sling debris outward, keeping edges sharp for the next rotation so forward bite stays consistent across ruts, roots, and sticky creek crossings.

Flotation ribs that surf soft sand

In dunes, wide ribs and minimized voids spread vehicle weight to prevent dig-in. Continuous central bands reduce plowing, while rounded shoulders loop the contact patch smoothly. Airing down enlarges footprint length, letting the tire glide over crests instead of knifing down steep slip faces.

3D sipes that grip on ice and packed snow

Winter-focused all-terrain blocks use full-depth 3D sipes that interlock under load, preserving block stiffness while creating thousands of biting edges. Micro-pumps drain thin water films, helping the rubber contact microscopic asperities and shortening stopping distances on wind-polished intersections and shaded alpine descents.

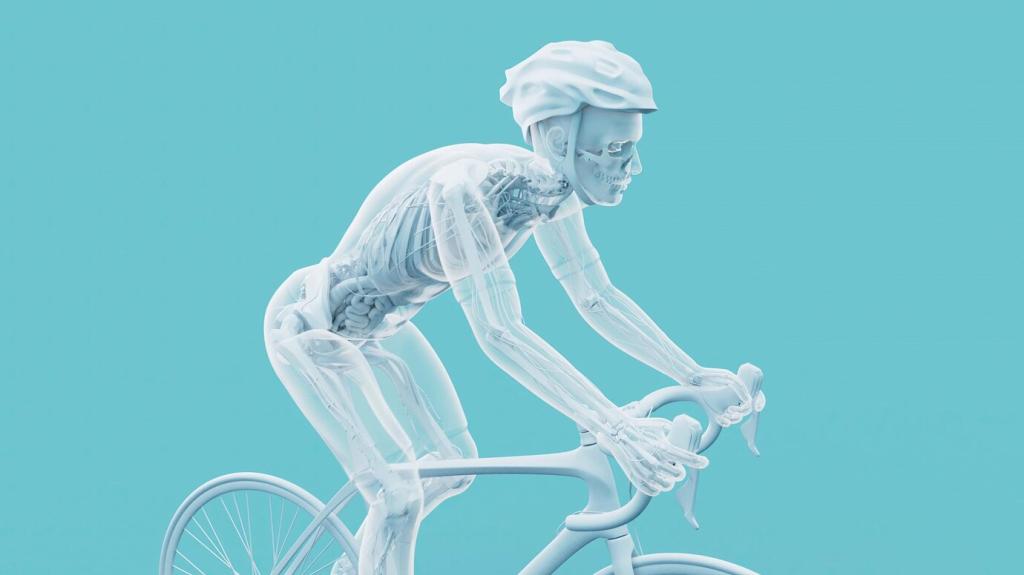

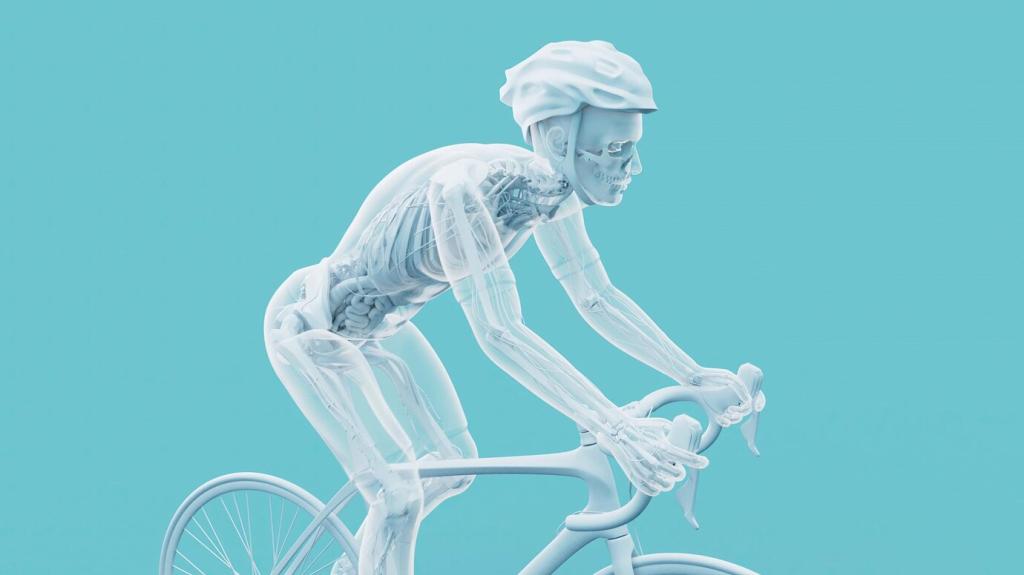

Sidewalls, Beads, and Carcass Architecture

Lightweight aramid layers add formidable tear resistance without a weight penalty, allowing sidewalls to flex over rocks while shrugging off sharp shale. Combined with variable-angle cords, the carcass relaxes vertically but stays laterally stable, improving steering precision on rutted trails and sudden off-camber surprises.

Sidewalls, Beads, and Carcass Architecture

High-tension bead bundles, sometimes paired with rim-locking geometries, keep the tire seated during low-pressure crawling. The secure interface reduces burping and protects the rim flange, empowering drivers to chase traction at single-digit PSI without fearing a sudden unseat on tricky ledges or stair-steps.

Contact patch analytics from in-tire accelerometers

Tiny accelerometers monitor vibration signatures that correlate with footprint shape and slip onset. By recognizing patterns, systems alert drivers to underinflation or overload before heat spikes. The feedback loop turns guesswork into guidance, especially when alternating between highway miles, rocky climbs, and sandy approaches.

Predictive wear models that learn your route mix

Data from temperature and pressure sensors feeds models that estimate wear across zones of the tread. If your weekly mix includes gravel detours and urban braking, the system can propose rotations or pressure tweaks to even wear and extend life without dulling terrain-specific performance.

Dashboards that translate data into action

App dashboards visualize load distribution, casing temperature, and pressure drift over time. Color-coded cues recommend air-down targets for washboards or re-inflation before pavement. Clear insights reduce sidewall stress, keep compounds within their ideal window, and ultimately boost traction where it truly counts.

Bio-based oils and recycled carbon black

Replacing petroleum oils with soybean or citrus-derived alternatives reduces volatility and improves low-temperature pliability. Recovered carbon black from end-of-life tires closes loops, trimming emissions while maintaining reinforcement. Thoughtful blending sustains durability, letting your tires bite confidently without leaving an oversized environmental footprint behind.

Low rolling resistance meets all-terrain bite

Engineers shape tread blocks to minimize energy loss on-center, then sharpen edges at the shoulders for off-road traction. Aerodynamic sidewall textures and light-but-strong carcasses reduce parasitic drag. The combined effect saves fuel on approach roads while keeping crawl-ready grip when the pavement ends abruptly.

Retreading and extended-life strategies

For fleets and heavy tourers, retreadable casings and modular tread layers stretch service life dramatically. Regular rotations, terrain-matched pressures, and timely cleanouts prevent irregular wear. The payoff is fewer casings consumed, more consistent performance, and budget space for safety-critical gear on your next long loop.

Testing Grounds: From Lab to Landscape

On frozen proving grounds, engineers measure braking and lateral grip as siping patterns evolve. One test crew recalls shaving noticeable stopping distance after adding micro-pumps to a block cluster, turning nerve-wracking glazed intersections into manageable events during long subzero durability runs.

Testing Grounds: From Lab to Landscape

In dunes, telemetry reveals when lugs churn instead of surf. Tread ribs got widened and shoulder scoops softened to reduce heat buildup and trenching. A rally team reported smoother crest transitions and lower casing temperatures during multi-hour stages, improving pace without punishing fuel consumption.

Choose Confidently: A Practical Tire Selection Guide

Aggressive mud patterns impress, but can hinder wet braking or drone on highways. Hybrid all-terrains balance commuting with weekend trails. Clarify your typical surfaces, climate, and towing needs, then let pattern, compound, and carcass strength follow the mission instead of chasing trend photos.

Morphing tread blocks that react in real time

Concepts use embedded actuators and tunable elastomers to stiffen or soften lugs as sensors detect slip or temperature changes. Imagine shoulder blocks firming for cornering on dry rock, then relaxing for snow compliance minutes later without swapping tires or compromising your day’s plan.

Airless lattices that refuse flats

Engineered lattices distribute loads through resilient cells, eliminating punctures and bead unseating. By tuning cell geometry, designers target comfort on-road and impact resistance off-road. The promise is predictable performance despite nails, cactus spines, or shale shards that would sideline traditional pneumatic setups.

Field-replaceable 3D-printed tread skins

Modular skins could let expedition teams print terrain-specific patterns at depots, then wrap a durable core casing. Swap from winter siping to desert ribs in hours, reducing cargo and downtime. Standardized interfaces would keep alignment true while enabling local materials to support remote missions.